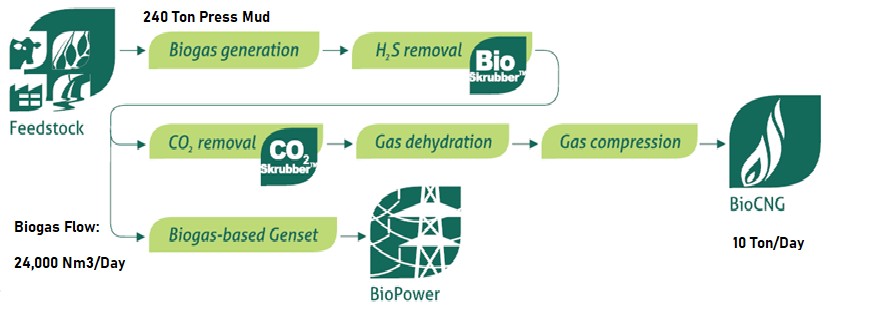

The project consists of Biogas Generation from organic material such as Press Mud and biogas cleaning for producing BioCNG.

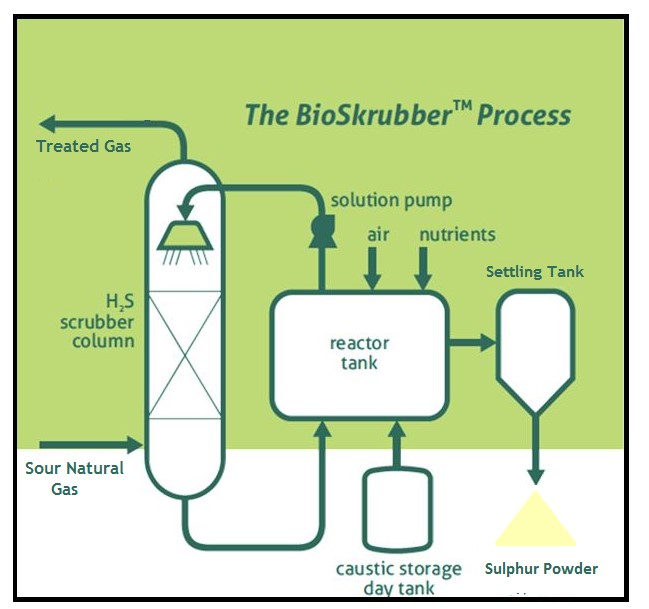

The Biogas Cleaning to BioCNG plant consists of BioSkrubberTM system designed to reduce the H2S less than 20 ppm, and CO2 System, to remove the CO2 up to less than 3 % and moisture level to less than 5 mg/m3 in clean biogas.